CYBERFAQ

(Week 29)

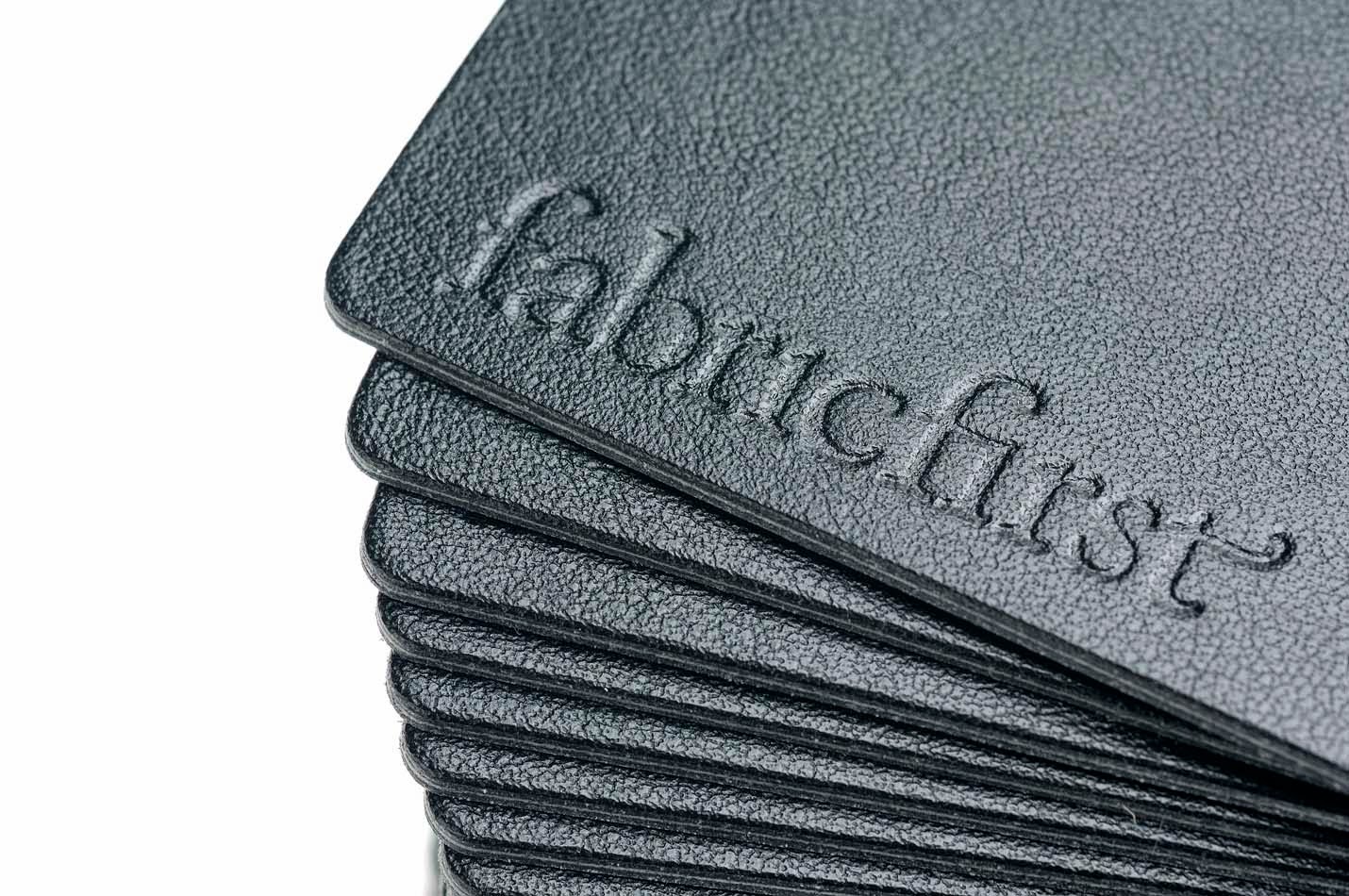

die cutting

Die cutting involves a specialised tool to cut, shape and form a wide variety of shapes and components with various materials available from flat sheets of paper, board, lenticular, Polyprop, etc.

1. Can be generally customised and matched to any size that you require.

2. As the shape can be formed in one punch, the rate in which it can make identical forms is very quick

3. Is relatively cost effective compared to other methods

Disadvantages

1. Not as precise as other methods such as laser cutting (Week 15) which involves far more detail and precision.

Considerations

Die cutting is usually used to produce flat objects that can be made into the desired shape . Suitable for, boxes, paper products and flat plastic pieces. The suitable order size, is anything from 500 upwards.

2. As the shape can be formed in one punch, the rate in which it can make identical forms is very quick

3. Is relatively cost effective compared to other methods

Die cutting is usually used to produce flat objects that can be made into the desired shape . Suitable for, boxes, paper products and flat plastic pieces. The suitable order size, is anything from 500 upwards.

No comments:

Post a Comment